Testing Capabilities

Testing services for medical devices are crucial in ensuring their safety, efficacy, and compliance with regulations. These services include biocompatibility testing to assess tissue interaction, sterilization validation to confirm effectiveness, material testing for suitability, and electrical and mechanical testing for performance evaluation. Additionally, there are usability and human factors testing, environmental testing for extreme conditions, regulatory compliance testing, and assessments for software, cybersecurity, and environmental impact. These evaluations are essential for verifying the quality and safety of medical devices before their approval for use.

Features that set us apart

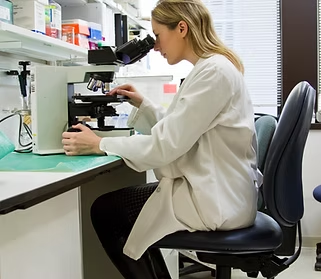

Biocompatibility Testing

Evaluating the device's interaction with living tissues to ensure it doesn't cause adverse reactions.

Sterilization Validation

Verifying the effectiveness of sterilization methods such as steam, ethylene oxide, or gamma radiation.

Material Testing

Assessing the suitability of materials used for the device, including chemical, mechanical, and thermal properties

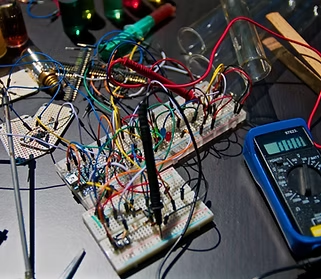

Electrical and Mechanical Testing

Examining the device's electrical performance, durability, and mechanical integrity.

Features that set us apart

Performance and Functional

Testing the device's intended functions and performance under various conditions.

Software and Cybersecurity

Ensuring the safety and security of software components in medical devices.

Usability and Human Factors

Assessing how easily the device can be used by healthcare professionals and patients.

Environmental Testing

Evaluating how the device performs under extreme conditions, such as temperature and humidity variations.

Regulatory

Compliance

Ensuring that the device meets the requirements of regulatory bodies like the FDA or CE marking in Europe.

Environmental

Assessment

Assessing the device's impact on the environment and its biodegradability.